2019-03-01

Safety and efficiency in the drivetrain

RINGSPANN places new jaw couplings at the centre of its Hannover Messe presence

RINGSPANN’s ongoing productive offensive in the field of non shiftable shaft couplings since Autumn 2018 has been very well received by designers and developers in industrial drive technology. Thanks to the completion of existing models and the incorporation of new coupling types in its overall range, the company now offers many alternatives for the realisation of safe connections between the various units and components in the drivetrain. At Hannover Messe, RINGSPANN will be providing a glimpse into its current shaft coupling portfolio. At the centre of its exhibition programme are elastic elastomer jaw couplings for dynamic applications.

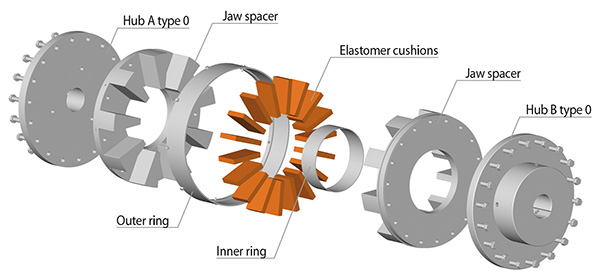

Bad Homburg, March 2019. – What RINGSPANN has to offer designers and engineers in industrial drive technology since October 2018 in the field of non shiftable shaft couplings is rich in alternatives: A selection of eight models with nominal torques ranging from 2.0 to 1,299,500 Nm, spanning almost all technically relevant shaft coupling types that you need in industrial drive technology to compensate axial, radial and angular displacements. Overall, the current RINGSPANN portfolios includes flange, flexible and cone clamping couplings, gear couplings, grid couplings and disc couplings, all the way through to pin-and-bush and jaw couplings. Product developers, engineers and plant manufacturers in all sectors are thus granted plenty of leeway for the design of rigid, torsionally stiff and elastic connections between shafts, motors, gearboxes and machines. At this year’s Hannover Messe, RINGSPANN will be providing an overview of its expanded coupling range in Hall 25, Booth D13 by means of a number of exponents. The company hereby focuses particularly on the new jaw couplings of the REK series, which feature replaceable elements and spiders made of elastomers or synthetic rubber.

Fail safe and maintenance free

“The use of jaw couplings for elastic shaft connections is on the rise in Europe. They are fail safe and maintenance free, and are often significantly more compact in construction than pin and bush couplings. Our new REK model is particularly interesting for manufacturers of pumps, compressors, ventilators, stirrers and belt conveyors, as well as for tool machines and crane trolley manufacturers – to name just a few key user groups”, says Martin Schneweis, the responsible product manager for shaft couplings at RINGSPANN. The current offer of the company ranges from the classic jaw couplings of the REK … DCO series with curveded spiders and nominal torques from 9.6 Nm, to the couplings of the REK … DQO series with rectangular damping elements and nominal torques of up to 169,000 Nm. In terms of bore diameters – another key selection criterion for designers – these models range from 6.0 to 340 mm. All RINGSPANN jaw couplings also meet the explosion protection parameters in accordance with ATEX (Declaration of Conformity in according with ATEX 2014/34/EU).

Quick switch and replacement

At RINGSPANN’s Hannover Messe booth in Hall 25, designers and development engineers in industrial drive engineering can receive first-hand detailed information on which practical and functional advantages the jaw couplings offer. So you can find out, for example, that the elastomer damping elements with the couplings of the REK…DQO model can be very easily and quickly replaced – without disassembling the drivetrain. “The jaws, too, can be replaced quickly in the event of damage, since the hubs of the couplings are spilt and the drive plates can be removed radially”, says product manager Martin Schneweis.

With the ongoing product offensive in the field of non shiftable shaft couplings since Autumn 2018, RINGSPANN has achieved an important milestone on its way to becoming a one-stop supplier for high-grade components of drive technology. The company may have already been involved in the development and manufacture of safety and starting couplings for more than 60 years, and yet Martin Schneweis stresses: “The now completed expansion of our coupling range is as yet unrivalled in RINGSPANN’s history”.

By the way: If anyone would like to get an overview of the new RINGSPANN portfolio of shaft couplings in advance of Hannover Messe, you can download the current product catalogue here for free. Here, all coupling types are listed by model and area of application: The cone clamping couplings and tru-line flange-couplings for rigid connections; the gear, disc and flexible couplings for torsionally stiff connections; the grid couplings for initially elastic and later torsionally stiff connections; and the pin-and-bush und jaw couplings for elastic shaft connections.